Egg Production and Processing Plant Project in Latvia

PC Group: Strategic Partner and Innovator in Sustainable Energy and Resource Management for GALLUSMAN's Advanced Egg Production Plant in Latvia

As a trusted partner in green energy and advanced resource management, PC Group proudly contributes to the development of GALLUSMAN's state-of-the-art egg production and processing complex. This collaboration underscores PC Group's commitment to fostering innovative solutions that align with the sustainability goals and the growing demand for high-quality, eco-friendly food production practices.

The company - GALLUSMAN SIA, is aiming to secure funding to establish a modern egg production and processing plant complex in Latvia. The project will be developed in multiple phases, with the production infrastructure gradually expanded at each stage.

Scope of the entire project

- 16 hen houses for up to 5.36 mln laying hens

- 9 young bird houses for up to 1 mln young birds

- Egg collecting, grading and quality control plant

- Egg processing plant and integrated warehouses

- Grain reception, pre-processing and storage plant

- Bird feed production plant

- Heat production plant

- Manure processing and organic soil fertilizer production plant

- Waste water treatment plant

Location of the Project

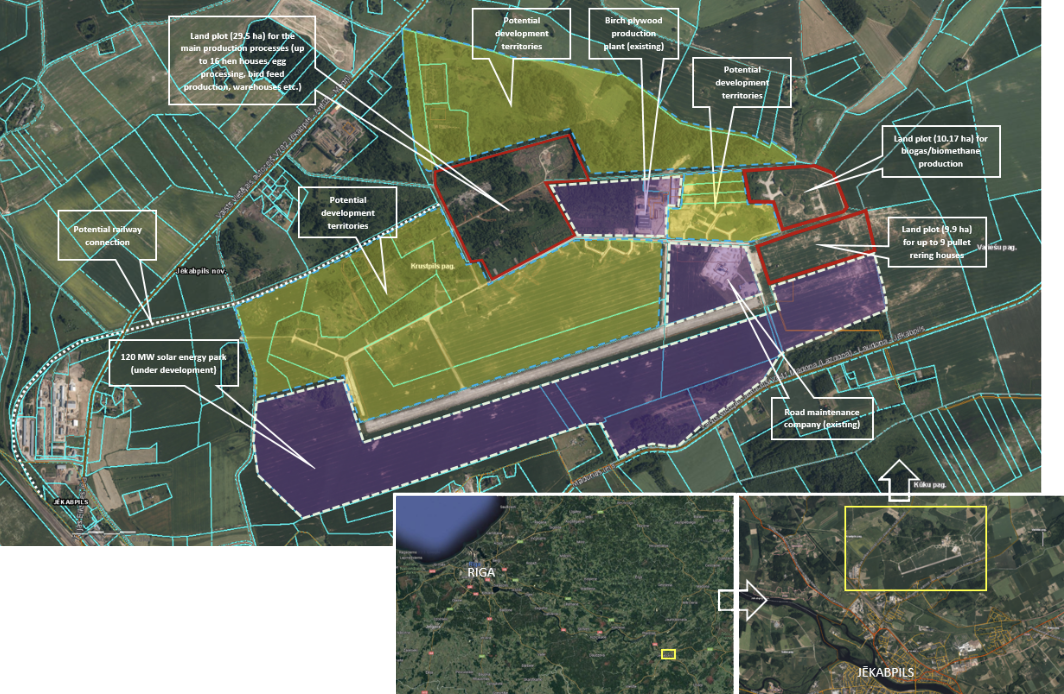

The selected location for development of the Project is the territory of the former military airfield in the Southeast part of Latvia, near the city of Jēkabpils (population: about 22 thousand; distance to Riga: 130 km, distance to Lithuania border: 70 km).

The infrastructure of the egg production and processing plant is planned to be located on three land plots - 29.48 ha, 9.9 ha and 10.17 ha. The land plots are included in the territory of the Industrial development (as per the Territorial planning approved by the Jēkabpils Region Municipality), where the planned activity is permitted, without necessity for any transformation or changes to the territorial planning.

The main advantages of the selected location

- Available natural gas and electricity infrastructure

- Vicinity of the internationally important transport infrastructure, which consists of roads and railways

- City of Jēkabpils itself which is the main hub for transporting of grain produced in the Latgale region to the Latvian sea ports.

- The city of Jēkabpils is one of the largest cities in Latvia and regional center of the economic activity

Financing of the Project

Market situation and planned customer network

The EU is currently moving away from using of cages in animal farming due to intense lobbying by the animal rights organizations. Some of the EU member states have already adopted their own regulations to ban use of caged systems for egg production. All cage systems for hens are already banned in Austria, Luxembourg and Switzerland. Germany, Czech Republic and Slovakia have enacted bans that will come into force in 2025, 2027 and 2030, respectively. France has recently banned the installation of any new cages. Also, many of the largest EU food industry companies and retailers have announced or are planning to phase out the sale and use of eggs from caged hens (incl. imported) by 2025.

As a result of the upcoming (and already happening) major changes for the EU egg production industry, the existing EU egg producers have commenced reorganization of their production processes by replacing cage systems. However, these changes are not happening quickly (especially in Eastern Europe) due to the significant investments and time required.

It is certain that going forward the most common egg production method in EU will be Barn. This also means that more laying hens will be required to produce the same volume of eggs and egg products as before due to the lower densities of birds allowed at the production sites and lower productivity of birds, i.e. the more production sites (and bird places) will also be inevitably needed.

Given the noted, this is the best time for the development of the Project, as it would allow to timely guarantee the stable positions in the EU Barn eggs market.

Planned products

Egg production at the GALLUSMAN egg production and processing plant is planned to be cage-free (i.e. #2 method of keeping laying hens, or eggs laid in a barn - "Barn"). Total of up to 0.44 billion shell eggs to be produced by completing of the first stage of the Project (1,66 milj birds). Shell eggs produced are planned to be sold to the egg processing and wholesale companies in Europe, thus optimizing the production costs and investments needed (for egg grading and packaging infrastructure) at the initial stage of the Project.

Sales team

The sales team will be comprised of the industry professionals from the company Ovostar Europe SIA. Since 2015, this company has been mostly engaged in import and trade of Ukraine origin eggs and egg products to the markets of EU, Middle East and Asia with annual turnover exceeding 50 million EUR.

The main advantages of the Project

Lower energy costs

Overall, electricity costs in Latvia are lower than in W/C Europe. 120 MW solar power plant is under construction in Jēkabpils (next to the planned egg production plant) by end of 2025. This power plant will focus on B2B sector.

Lower transportation costs

There are lower transportation costs (road transport) for transporting of goods from Latvia to Europe, comparing to transporting of goods from W/C Europe to other W/C countries. The average transportation costs for eggs from Latvia to W/C Europe is about 0.60 EUR/100 pcs.

Lower energy costs

Overall, electricity costs in Latvia are lower than in W/C Europe. 120 MW solar power plant is under construction in Jēkabpils (next to the planned egg production plant) by end of 2025. This power plant will focus on B2B sector.

Preliminary works done

There is an agreement concluded with the designing company on preparation of the construction design project. Certain designing works had already been commenced (and completed).

Extra income possibilities

Anaerobic digestion of manure and production of biogas, which can be transformed into biomethane to be injected in the natural gas grid for a profit.

Lower labor costs

The labor costs are expected to remain lower in comparison with the W/C Europe and are comparable with the other Eastern Europe countries.

Effectiveness of the production process

The new production plant project will include the most effective production solutions (by reducing time and distance for movement of raw materials and finished products between the production process stages) based on the previous experience and the technological solutions of the team.

Call for Strategic Investors

Join PC Group in Revolutionizing Sustainable Food Production

PC Group invites visionary investors to become strategic partners in the development of GALLUSMAN's cutting-edge egg production and processing plant in Latvia. This landmark project is poised to transform the industry with its commitment to sustainability, efficiency, and innovation. By integrating advanced energy management systems, renewable energy solutions, and resource-efficient technologies, the project aligns with the EU's drive toward eco-friendly and cage-free food production.

Why Invest?

First-Mover Advantage: Capitalize on the growing EU market for barn eggs amidst regulatory shifts banning caged systems.

Proven Expertise: Collaborate with PC Group, an established leader in green energy and resource efficiency solutions.

Sustainable Returns: Benefit from reduced production costs, lower energy expenditures, and access to cutting-edge technologies.

Market Expansion: Market Expansion: Leverage strategic location advantages with proximity to key EU markets and optimized logistics.

Your Role as a Strategic Investor

As a strategic investor, you'll join an ambitious project that addresses global challenges in food production and energy management. Your partnership will ensure the successful completion of this high-impact initiative while positioning you at the forefront of sustainable and profitable innovation.

Contact PC Group today to explore this unique investment opportunity and shape the future of sustainable food production together.

Let us know if you're ready to discuss the next steps in this transformative journey!